Description

Introduction to Wiggle Wire Wire-lock Channel Slots

Wire-lock channel slots for greenhouse structures serve as the core fixing components for covering materials (such as films). Typically formed by hot-dip galvanized steel plates or extruded aluminum alloys, they feature corrosion resistance and high strength, enabling long-term use in greenhouse environments with high humidity and intense UV radiation.

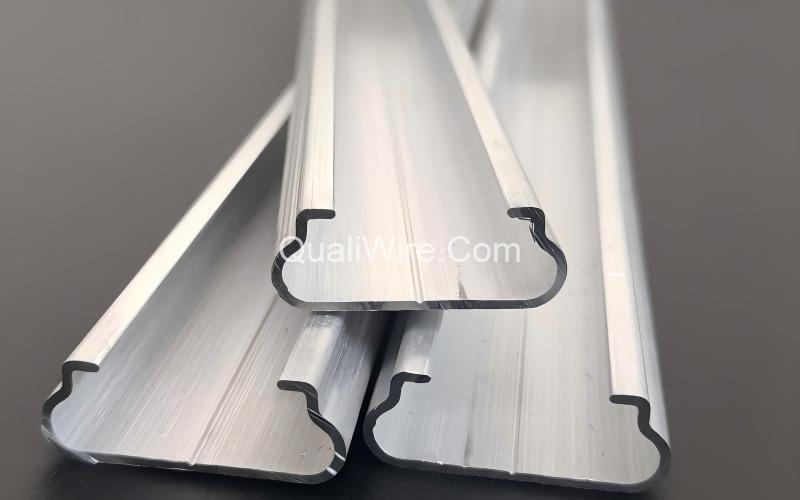

The cross-section of wire-lock channel slots presents a “U”-shaped or special groove structure. The inner groove is designed with a track compatible with spring wiggle wires, which tightly press the covering materials into the slots through the elastic deformation of the springs, forming a sealed and fixed connection. As a key node in the greenhouse covering system, the quality of channel slots directly affects the greenhouse’s sealing performance, wind load resistance, and thermal insulation, making them indispensable basic components in modern agricultural facilities.

Types of Wire-lock Channel Slots

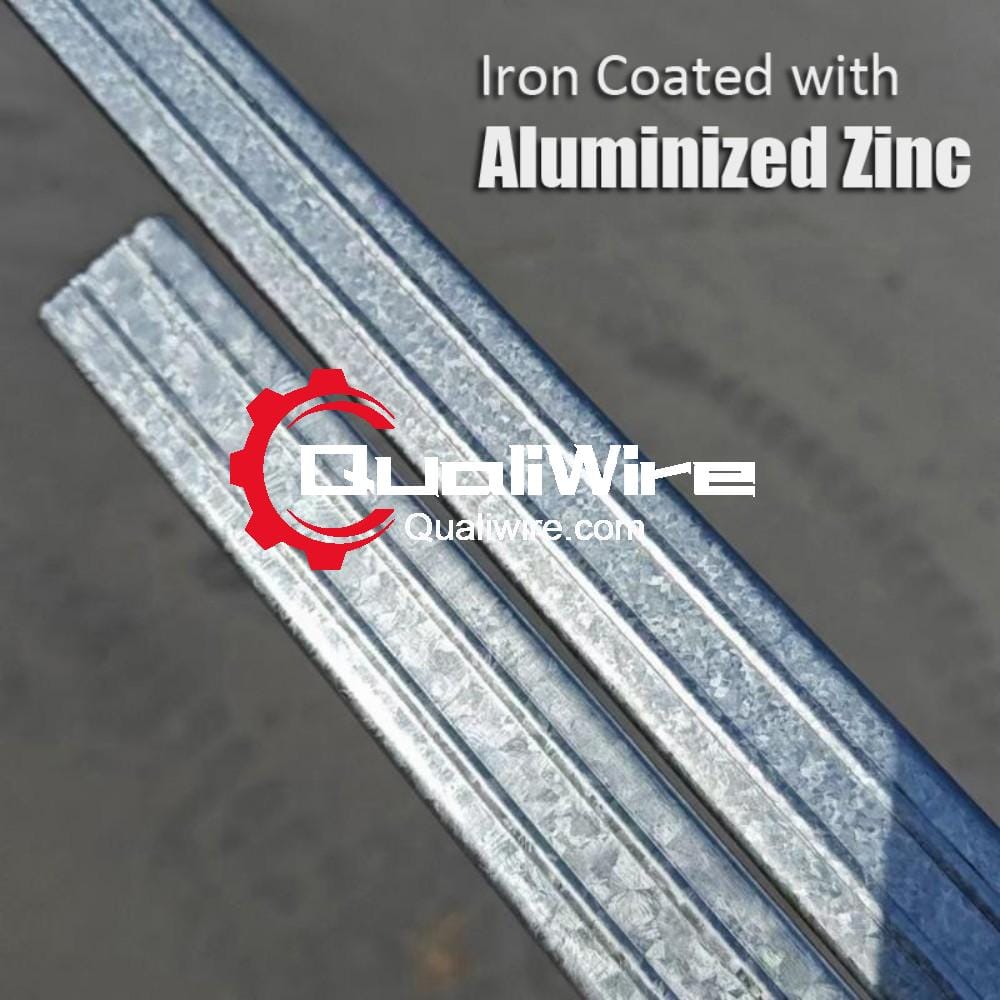

Currently, wire-lock channel slots are available in various materials, including aluminized zinc, stainless steel, aluminum alloy, and nano-coated types. Among these,aluminized zinc and aluminum alloy are the most widely used due to their excellent service life and corrosion resistance. These two materials strike an optimal balance between durability and anti-corrosion properties, making them preferred choices for most greenhouse applications.

Qualiwire® produces 20,000 meters of spring wiggle wire wire-lock channel slots daily. The primary types include aluminized zinc and aluminum alloy, two materials chosen for their exceptional durability, corrosion resistance. Each card slot is standardized at 4 meters in length, striking a balance between transportation convenience and practical usability. These wire-lock channel slots are available in various thicknesses to accommodate different application scenarios.

Production Video

Tommy –

Good job

Angle –

What is minimum order quantity ?